Laser Coating Removal Robot for Aircraft

source:photonics.com

keywords:

Time:2016-12-06

SCHIPHOL-RIJK, Netherlands, Dec. 5, 2016 — A robot equipped with a 20-kW CO2 laser will soon be removing paint from commercial and military aircraft, both big and small.

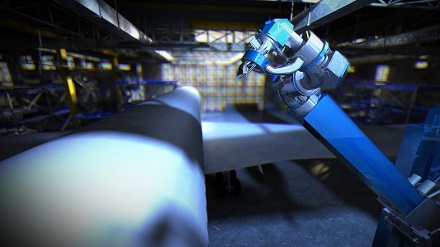

LCR robot to be used to remove paint from military aircraft. Courtesy of LR Systems BV.

The Laser Coating Removal (LCR) robot from LR Systems BV will allow a faster and cleaner removal process than previous methods and lead to less time on the ground for the aircraft. Current stripping of aircraft is done with chemicals and manual sanding, which is time-consuming, unhealthy and costly, as aircraft need this done every six years. Using a laser cuts the turn-around time in half and reduces the CO2 footprint by up to 65 percent.

Paul van IJsselstein, CEO of LR Systems BV, told Photonics Media the applied laser includes a laser beam path control system, a high speed polygon scanner and a closed loop control system; it is able to remove paint of any color layer by layer.

“The actual speed is 40 m2/h for a paint thickness of 180 µm (7 mils) over large areas and fully automated. It can reach up to 25 m, gets under an aircraft with only 1 m space under the belly, and follows the actual contour of the aircraft,” said IJsselstein. “It positions itself, it checks on obstacles, and protects the aircraft and human safety with many duplicated sensors.”

Potentially, an LCR robot system working on a C-130 aircraft could finish the stripping portion of the job in 11 hours; that is with a robot on each side. Start to finish, taking into consideration aircraft preparation, the repainting could begin within 36 to 48 hours later.

The first LCR robot of its kind must pass testing and certifications by DEKRA — everything from the evaluation of the safety concept, testing of the robot components, and factory acceptance testing on location — before it can be officially put into use.

Bert Zoetbrood, CEO of DEKRA and head of the product testing and certification division, told Photonics Media the entire testing and certification process will take place over a nine-month period.

“DEKRA aims to provide proof of compliance with all regulatory requirements, amongst which are electrical safety and electromagnetic compatibility,” said Zoetbrood. “Our involvement in supporting LR Systems in the development and deployment phases of the LCR robot ties in seamlessly with our ambitions; we provide integrated services globally for innovative products every step of the development process until the new product reaches its market.”

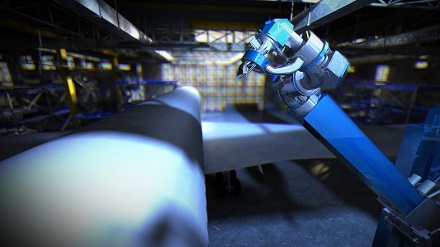

Laser Coating Removal robot with 20kW laser. Courtesy of LR Systems BV.

The LCR robot combines high-power laser technology, robot kinematics, automated guided vehicles, positioning and safety design, and real-time process and object control.

According to IJsselstein, “It is technology 2.0 in the world of robots for paint stripping, surface treatment processes, and robots adaptable for large structures. The performance is supporting the business need of aircraft owners.”

Currently being tested in the aerospace market, the LCR robot could adapt to other markets that have the same need to remove paint quickly and safely. A paint robot based on the same architecture will follow in 2018.

The Laser Coating Removal (LCR) robot from LR Systems BV will allow a faster and cleaner removal process than previous methods and lead to less time on the ground for the aircraft. Current stripping of aircraft is done with chemicals and manual sanding, which is time-consuming, unhealthy and costly, as aircraft need this done every six years. Using a laser cuts the turn-around time in half and reduces the CO2 footprint by up to 65 percent.

Paul van IJsselstein, CEO of LR Systems BV, told Photonics Media the applied laser includes a laser beam path control system, a high speed polygon scanner and a closed loop control system; it is able to remove paint of any color layer by layer.

“The actual speed is 40 m2/h for a paint thickness of 180 µm (7 mils) over large areas and fully automated. It can reach up to 25 m, gets under an aircraft with only 1 m space under the belly, and follows the actual contour of the aircraft,” said IJsselstein. “It positions itself, it checks on obstacles, and protects the aircraft and human safety with many duplicated sensors.”

Potentially, an LCR robot system working on a C-130 aircraft could finish the stripping portion of the job in 11 hours; that is with a robot on each side. Start to finish, taking into consideration aircraft preparation, the repainting could begin within 36 to 48 hours later.

The first LCR robot of its kind must pass testing and certifications by DEKRA — everything from the evaluation of the safety concept, testing of the robot components, and factory acceptance testing on location — before it can be officially put into use.

Bert Zoetbrood, CEO of DEKRA and head of the product testing and certification division, told Photonics Media the entire testing and certification process will take place over a nine-month period.

“DEKRA aims to provide proof of compliance with all regulatory requirements, amongst which are electrical safety and electromagnetic compatibility,” said Zoetbrood. “Our involvement in supporting LR Systems in the development and deployment phases of the LCR robot ties in seamlessly with our ambitions; we provide integrated services globally for innovative products every step of the development process until the new product reaches its market.”

Laser Coating Removal robot with 20kW laser. Courtesy of LR Systems BV.

The LCR robot combines high-power laser technology, robot kinematics, automated guided vehicles, positioning and safety design, and real-time process and object control.

According to IJsselstein, “It is technology 2.0 in the world of robots for paint stripping, surface treatment processes, and robots adaptable for large structures. The performance is supporting the business need of aircraft owners.”

Currently being tested in the aerospace market, the LCR robot could adapt to other markets that have the same need to remove paint quickly and safely. A paint robot based on the same architecture will follow in 2018.

MOST READ

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

PRODUCTS

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>