Femtosecond Lasers for Use in Additive Manufacturing

source:3D PRINT.COM

release:Nick

keywords: Femtosecond laser; additive manufacturing; 3D printing

Time:2017-09-14

Representative thermal picture of femtosecond laser (fs) vs current nanolaser (ns) in an additive machine

PolarOnyx, an additive manufacturing company based out of San Jose, California, has created a first-of-its-kind femtosecond laser-based additive system. Traditional DMLM (Direct metal Laser Melting) machines use what’s known as CW or Continuous Wave lasers. These lasers, although ideal for low-temperature parts such as aluminum and titanium, have shown to have challenges with higher-temperature materials such as tungsten and iron. Higher-temperature materials require quite a bit more energy to bond metal particles together as compared to their lower temperature counterparts. Due to this increase in energy, CW lasers must output much more laser power. However, their pulse duration (i.e. how long the laser stays on) does not change. Thus, surrounding metal particles are affected and what are known as “thermal stresses” are built into the part itself.

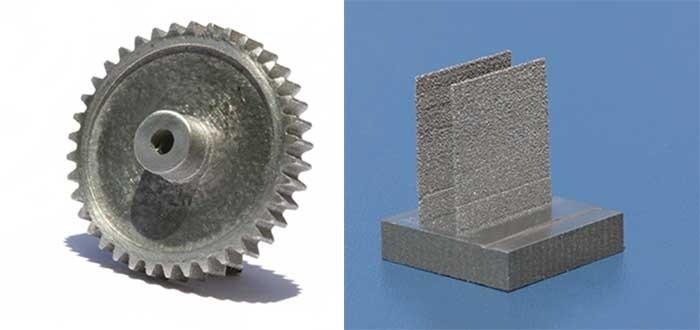

Samples of tungsten parts on tungsten substrates with various shapes and density. The gear has a 1/2-in. diameter (left), while the thin wall (right) has a thickness of 100 µm. [Image: PolarOnyx]

Additionally, Polaronyx was also able to successfully print iron powder directly on glass. Iron and glass have different but very close melting temperatures. With traditional CW lasers, the thermal buildup would have caused the glass to crack. However, with the femtosecond laser process and its ability to quickly fuse the iron powder, the iron was able to melt without causing any damage to the glass substrate.

Most interesting is PolarOnyx’s vision for a process whereby both the additive and subtractive properties of femtosecond lasers are integrated into one machine. Although metal additive has come a long way, there are still cases where complex features must be machined post-print. With femtosecond lasers, this task could be done all in one process with one machine. The femtosecond lasers could first additively build a layer, followed by a subtractive ablation of the same layer where tight machining dimensional tolerances are required.

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>